Solution Summary

Integrated Management System Without Local EMS

Instead of installing a local EMS at each individual plant, simply install iDERMS RTU and perform unified monitoring and control via a subscription-based web service.

Adapting to Market Changes Through Continuous Upgrades

Take advantage of various AI-based additional services such as equipment anomaly detection and task management, all based on collected big-data, at an affordable price.

Meet iDERMS PPC

Features

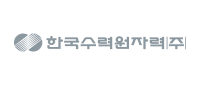

Unified Power Plant Monitoring and Control with iDERMS RTU

Instead of setting up local EMS at each power plant, we install standardized RTUs solely for data collection. There is no need to install servers on-site or worry about ongoing management. A single RTU can integrate with inverters, protection relays, and weather sensors, transmitting standardized data to the server and processing control commands, such as inverter on/off, as needed. To respond to continuously changing market rules, there is no need to upgrade local EMS. Necessary services can be subscribed to and managed through the web service.

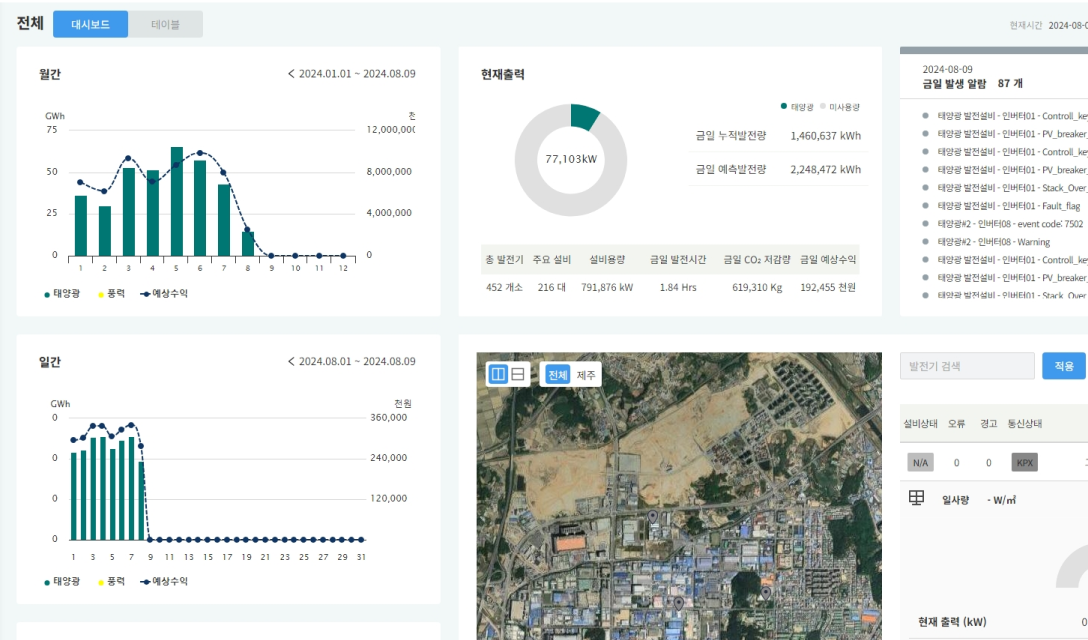

Standardization of Data Collection and Alarms for All Power Plants

Configure standard datasets for each site in the format desired by the customer, supporting data validation during site deployment. iDERMS PPC supports converting alarms from heterogeneous inverters and equipment into standardized messages, enabling the classification of individual alarm levels to enhance the convenience of alarm management for administrators.

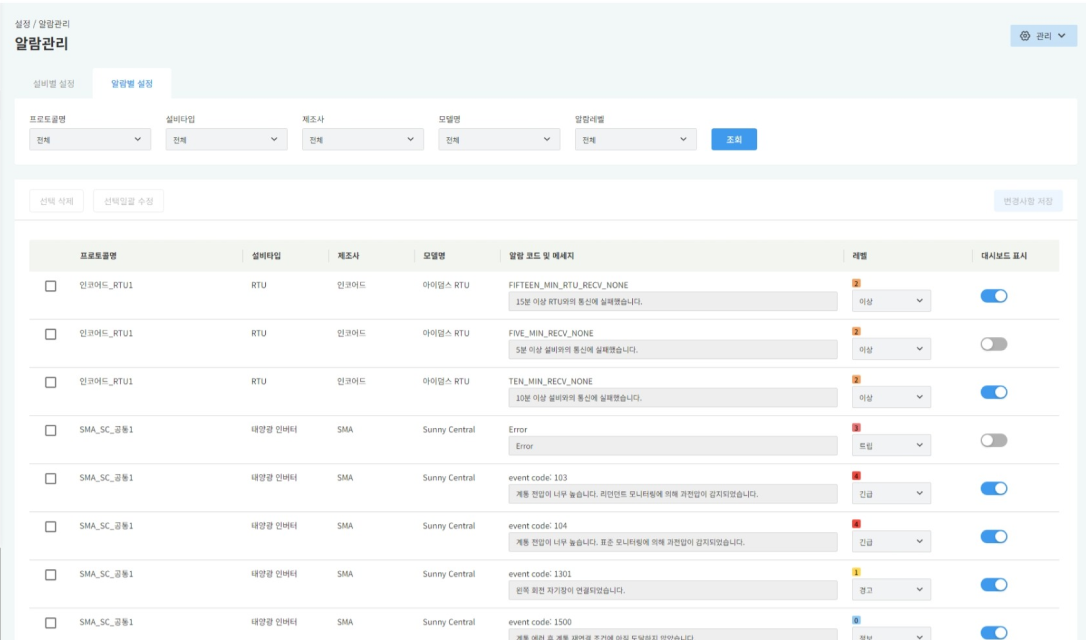

Data Analysis and Reporting for Power Plants

Unified data collection from all power plants allows for performance comparisons based on the same criteria and supports the generation of integrated reports for all plants. In addition to standard reports, we provide customized report generation that includes weather information and power market data according to customer requirements.

Additional Services

AI-Based Anomaly Detection

By standardizing and integrating all power plants, it is possible to compare each plant and equipment, enabling automated AI-based anomaly detection. We have established more than five performance metrics based on our expertise. Implementing automated anomaly detection rather than relying on the expertise of individual O&M managers enhances detection performance and increases the number of power plants that can be managed by each individual by over 50%.O&M Work Order Management

Provides work management functions integrated with generator equipment. Work orders can be issued by alarms from each power generation equipments, and by linking them to the final work report, it is possible to analyze the work history based on alarm types. The system includes approval stages for managers and features to decide on approval based on the work cost.Support for Exemption from Safety Engineer Requirement for 1MW~3MW

Provides work management functions integrated with generator equipment. Work orders can be issued by alarms from each power generation equipments, and by linking them to the final work report, it is possible to analyze the work history based on alarm types. The system includes approval stages for managers and features to decide on approval based on the work cost.